AlphaStruxure SVP and Chief Technology Officer Steve Pullins Joins Xendee's Board of Advisors

SAN DIEGO--(BUSINESS WIRE)--The Xendee Corporation, a leading DER and EV charging infrastructure design and operation software provider, announced...

For fleet owners and EV infrastructure developers, the installation of EV charging stations is a key component of their strategy for achieving zero-emission trucks and buses. Larger vehicles put a great deal of strain on the grid and its capacity to supply the megawatts of power required by dozens of commercial vehicles. In many cases, the grid has a considerable delay in providing the power required for these much larger loads. Xendee, a techno-economic DER, microgrid, and EV infrastructure design software platform, has helped customers model many multi-phased infrastructure build-out approaches. In this article, we will share some of the most popular approaches being used.

There are now EV offerings from all major and startup vehicle OEMs, so it's no longer a matter of waiting for electric vehicle production - it's a matter of building the infrastructure to support them. Some utilities are telling fleets it could be 12 to 24 months or more before their chargers can be energized, and up to 5 years if substation capacity is not available at the truck depot. Additionally, the supply chain continues to pose a challenge for charger installation timelines, especially for the larger transformers and switch gears (circuit breakers) required.

Where smaller Class 2-5 commercial trucks and vans can make do with smaller 11-19 kW overnight AC charging using existing site load capacity, the larger Class 6-8 trucks and buses need 50-350 kW charging, with some applications looking at 750 kW (Tesla) to 1.5 MW Charging (Charin-MCS). These extreme power levels can create a more “filling station” experience for the operator but require very large upgrades to the site equipment and interconnection upgrades with the utility. These often relate to months or even years of fleet electrification delays between the production of trucks and the actual ability to operate as part of a fleet.

A phased approach can help users save time and money while validating the first step in a comprehensive charging strategy. This can also help with the timeline requirements for local permitting and utility interconnection applications and sign-off. Xendee’s Design Software is able to model each of these phases to ascertain the sizing of key components and costs to purchase and operate for the optimum solution to power 20 Electric Semi Trucks.

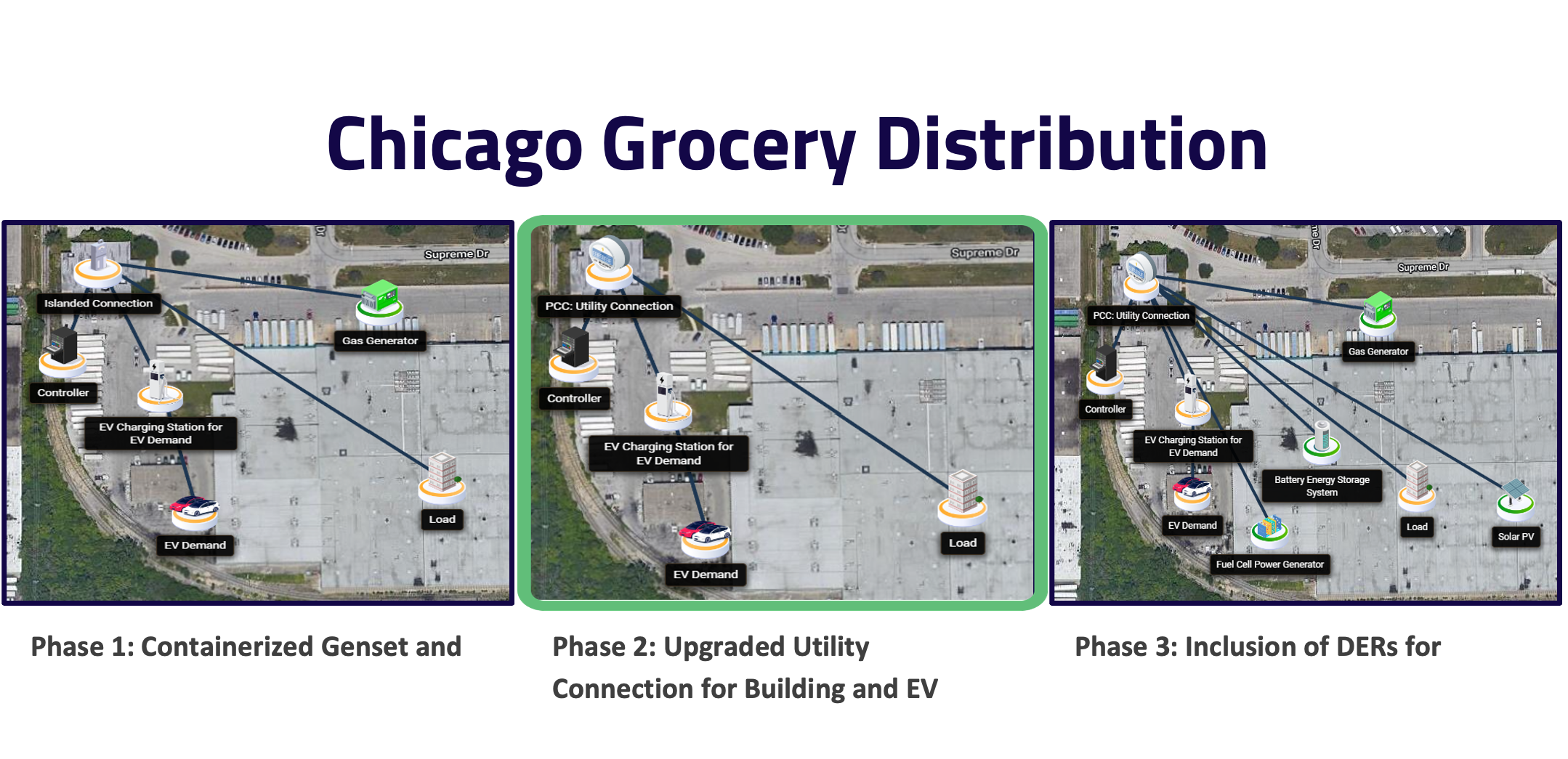

For this use case, we modeled two representative fleet depot locations for a national food service company in Xendee’s software. As different parts of the US can have various differences in weather and energy costs, two locations were chosen to model one depot near Los Angeles, CA, and a second depot near Chicago, IL.

In the above example, we look at powering 20 Freightliner eCascaida EV Class 8 Semi Trucks each running a 10-hour, 200-mile shift carrying 30,000 pounds of payload making 5 stops throughout the day. Xendee has a built-in EV Consumption Builder tool that uses a physics-based model to estimate the consumption of each truck’s battery for this route.

.png?width=800&height=331&name=unnamed%20(20).png)

Figure 1: Xendee’s EV Consumption Builder

The consumption builder calculates the load case and the charger availability, showing when the trucks could charge and how much energy is needed based on their route profile and timing. Even though trucks can start charging as soon as they pull into the yard, Xendee carefully chooses the optimal charging time based on the desired outcome. If minimizing cost is the project goal, Xendee may wait to charge in Phase 2 (Utility Connected) until the tariff is lower, which in LA falls after 9 PM or in some cases might be in the middle of the day. If minimizing carbon is the goal, it might start charging in phase 3 when the solar is still producing.

.png?width=800&height=328&name=unnamed%20(19).png)

Figure 2: EV Fleet Charging Schedule

Phase 1 - Powering With Temporary Gensets

Phase one of this project involves temporary power charging stations using transportable generators, or "gensets", which run on renewable fuels like renewable diesel and natural gas. The temporary charging will enable the trucks to operate on a shorter timeline while the permanent infrastructure is being built. It can also help with determining charging locations mid-route to further expand the applicability of the often shorter-range electric trucks.

Frequently, these units are mounted on trailers or in containers with fuel storage, power generators, DC fast chargers, and solar systems to charge trucks without any grid connection. By running these trucks today using the temporary genset, data is collected to substantiate and refine the complete infrastructure build-out for the near-term and long-term fleet conversion from diesel to electric.

Depending on the region, these modern emissions-controlled generators can have comparable carbon emissions to the regional power plant. If Renewable Natural Gas is used as fuel for the generators, the relative carbon emissions can be significantly better as is the case for Southern California and Chicago.

During this initial genset-supported phase of operation, the following key findings are obtained: what power energy and timing are needed to support the fleet's specific duty cycle, where charging systems should be located, how much electric trucks will cost during various duty cycles, and operational times, and how much greenhouse gas emissions will occur during the fleet buildout.

In parallel with this first phase of genset-supported EV Truck operation, work continues in the design and development for the permanent build-out of the charging systems. This work often starts with a grid/utility supporting connection to the charging stations often limited in capacity by what is available from the grid to support these loads which can often require upwards of 2-5 Megawatts of Power.

Phase 2 - A Grid-Supported Stage

The second “grid only” phase of the project will entirely rely on the utility to power the charging stations for the trucks. Significant site development work is often required for this more permanent infrastructure. The Utility may require an upgrade to their “in front of the meter” circuits, often called a “service drop” upgrade that also comes with a utility-owned, site transformer upgrade. Unfortunately, many of these transformers are in short supply, so it could take 9-15 months for the supply chain delays to be resolved. Also, the high-power switchgear or circuit breakers can further delay the systems.

Some innovative suppliers have cabinet combined systems of grid-to-site transformer plus switchgear, and sometimes charging hardware that can help lessen timelines and space claims at the site. The key to the project's success is selecting the optimum pieces of equipment early in the project and then putting those on order long before the vehicles arrive.

Xendee’s site design and modeling tools can help advise on the relative sizes of these equipment including performing a full electrical power flow analysis. Xendee can also create a one-line drawing of the transformers, switchgear, cabling/conduits, and charging equipment to use as part of the 30% initial site development plan submitted for permitting and load studies with the utilities as well as government agencies for permit approvals and grant funding.

Phase 3 - A Microgrid-Supported Solution

Lastly, the 3rd phase of a final microgrid-supported solution is planned and designed to enable the optimal site solution for the lowest overall levelized cost of energy (LCOE), or $ per kWh of energy cost. This results in the most affordable and often the lowest carbon solution with the bonus of hours or even days of resiliency to support the site and charging loads even during a power outage. In some cases, this might actually be the faster and easier solution than Phase 2, but that is often at the behest of the Utility and their interconnection timing. Having both Phase 2 and Phase 3 as parallel option paths gives the most flexibility to the fleet depending on the Utility timing and the availability of capital to purchase the microgrid equipment.

The site planner would model in Xendee their overall current and future energy needs to show a scalable multi-year approach to support their fleet electrification needs, often faster and at a lower cost than the time it would take a utility to bring in the capacity needed for a grid-only solution.

.png?width=800&height=301&name=unnamed%20(18).png)

Table 1: Annual Total Energy Costs and Emissions

In conclusion, adopting a phased approach in the implementation of electric semi-truck depots can offer significant time and cost-saving advantages. Through this strategy, coupled with the modeling capabilities of Xendee, the initial steps of a comprehensive charging strategy can be validated while the charging infrastructure is optimized. By embracing a phased approach, fleets can achieve faster and more cost-effective fleet electrification compared to relying solely on grid-only solutions.

Authors:

Clara Richardson, Greg Morgan

SAN DIEGO--(BUSINESS WIRE)--The Xendee Corporation, a leading DER and EV charging infrastructure design and operation software provider, announced...

SAN DIEGO--(BUSINESS WIRE)--The Xendee Corporation, a leading DER and EV charging infrastructure design and operation software provider, announced...

SAN DIEGO--(BUSINESS WIRE)-- Today, Xendee, the world’s leading Electric Vehicle (EV) fast-charging and distributed energy system design platform,...